Khoom siv

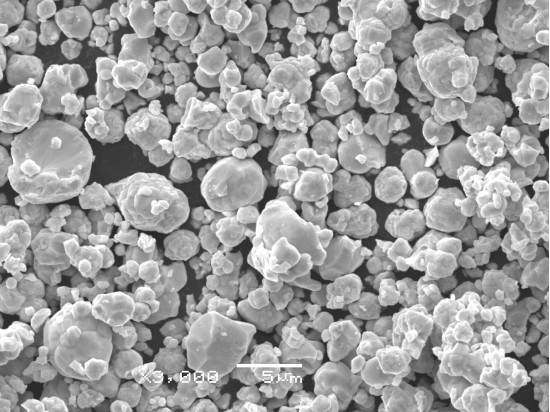

Peb siv cov ntaub ntawv txawv teb chaws thiab lub npe nrov hauv tsev "Peb Siab" thawj tungsten carbide los ntawm cov tuam txhab muaj koob npe raws li cov khoom siv raw.

Cov khoom siv tshwj xeeb

Pas Dej

Peb txais yuav cov txheej txheem thoob ntiaj teb advanced precision cemented carbide ntau lawm los tsim cov khoom siv hlau zoo.

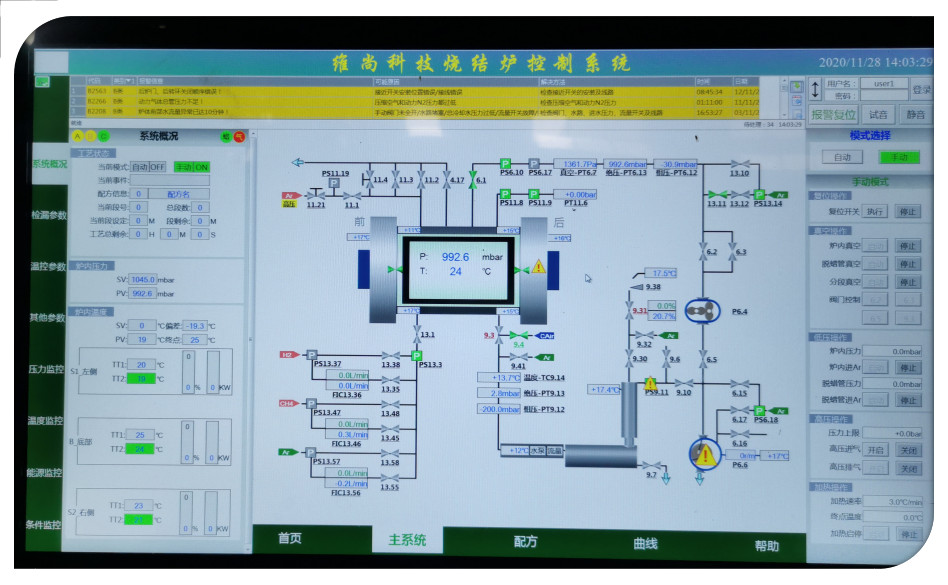

Peb lub pob zeb sib xyaw ua ke npaj rhiav tau hloov kho kom ua tiav cov kev txawj ntse thiab kev tswj hwm.Los ntawm ib qho kev tswj xyuas qhov system, peb tswj tsis tau xws li kev sib hloov ceev, lub sij hawm, qhov kub thiab txias, thiab lwm yam. Tej yam tsis xws luag tau ceeb toom tam sim ntawd, thiab cov ntaub ntawv kev tshuaj ntsuam xyuas yog ua los txuas ntxiv txhim kho cov txheej txheem tswj tsis tu ncua.

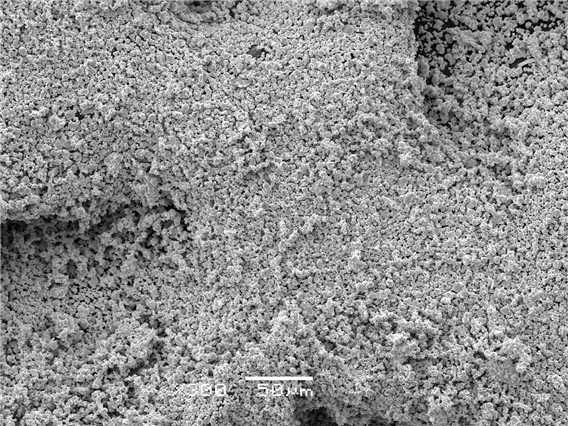

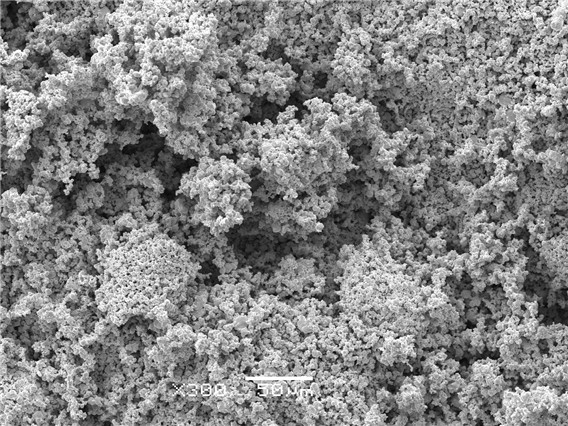

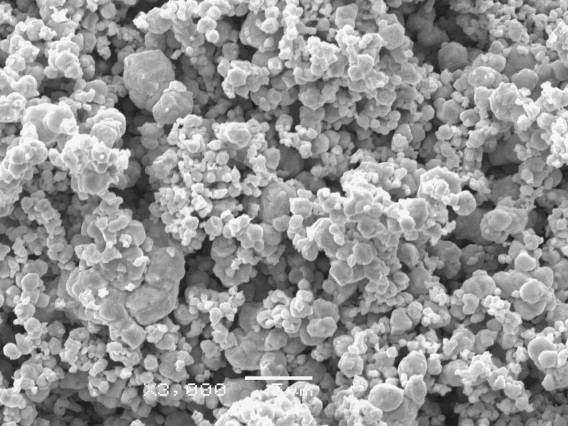

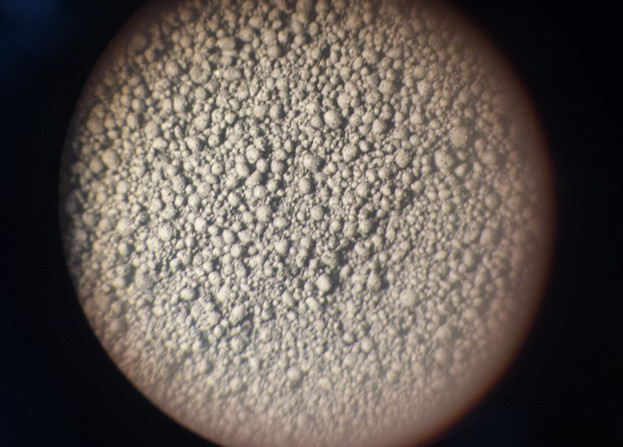

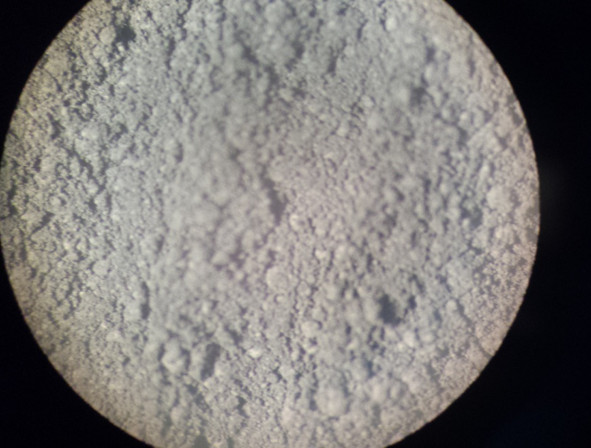

Peb siv internatio-nally advanced spray drying granulation tech-nology, uas muab piv rau cov tsoos phau ntawv granulation, zoo cais huab cua thiab plua plav, uas ua rau uniformly me me hmoov hais thiab zoo ib yam.

Compaction thiab Moulding Rhiav:

Nyob rau hauv peb cov txheej txheem compaction, peb ntiav machinery advanced nrog rau 60-tuj TPA tsis siv neeg xovxwm thiab 100-tuj tsis siv neeg hydraulic xovxwm.Qhov no ua rau uniformly faib cov khoom nyoos ceev thiab siab precision nyob rau hauv cov khoom qhov ntev.Lub rooj cob qhia tswj kev ua pa zoo, qhov kub thiab txias txhua xyoo thiab cov av noo tswj, nrog rau kev ntsuas huab cua kom huv si kom ntseeg tau tias qhov chaw tsim khoom tsis muaj paug thiab cov khoom zoo thoob plaws hauv cov txheej txheem tsim khoom.

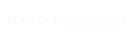

Hauv 50 xyoo dhau los, cemented carbide sintering thev naus laus zis tau dhau los ua qhov kev hloov pauv zuj zus los ntawm hydrogen furnaces mus rau lub tshuab nqus tsev, thiab thaum kawg mus rau cov cua sov siab.Lub siab-pab sintering tau tshwm sim raws li cov txheej txheem forefront alloy sintering thoob ntiaj teb.Txoj hauv kev no sib txuas ua ke debinding, nqus sintering, thiab siab sintering rau hauv ib kauj ruam, txo cov khoom porosity thiab ua tiav ib theem ntawm alloy density akin rau tag nrho cov ntaub ntawv ntom.

Nine-Step Quality Control Txheej txheem hauv Alloy Production:

1. Kev ntsuam xyuas ntawm Raw Material's Chemical and Physical Properties

2. Kev sim ua tau zoo ntawm Raw Material Ball Milling

3. Kev kuaj thiab kuaj lub cev ntawm cov khoom sib xyaw pob-milled

4. Kev txheeb xyuas los ntawm kev kuaj thiab kuaj lub cev ntawm cov khoom siv tshuaj tsuag-Milled

5. Kev Ntsuas Kev Ua Haujlwm Pib ntawm Compaction Calibration thiab Molding

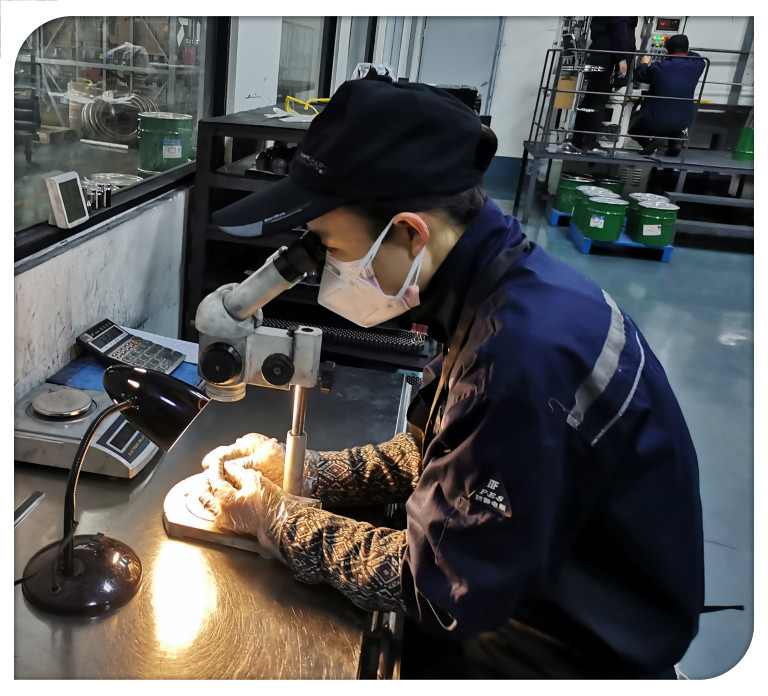

6. Kev tshuaj xyuas tus kheej ntawm kev tsim khoom zoo thaum lub sij hawm Compaction

7. Reinspection of Quality by Compaction Quality Personnel

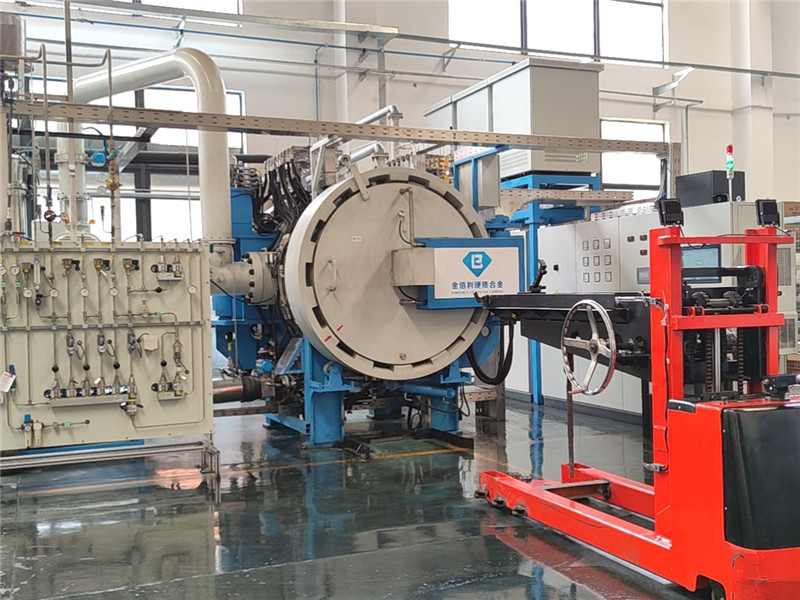

8. Kev ntsuam xyuas lub cev thiab cov cuab yeej cuab tam ntawm Sintered tiav cov khoom

9. Kev tshuaj xyuas cov khoom tiav cov qauv, qhov ntev, qhov tshwm sim, thiab qhov tsis zoo.